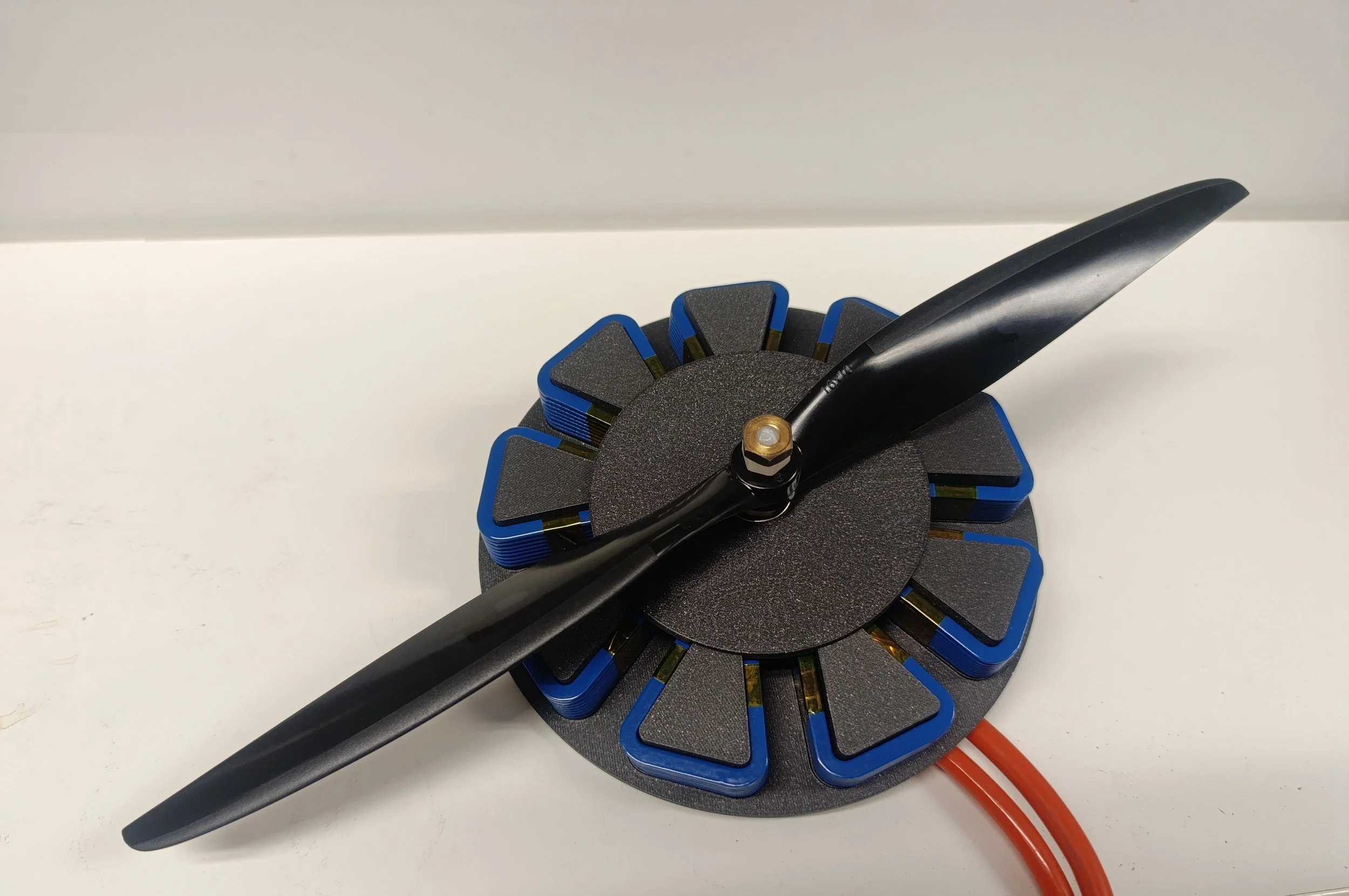

drive13

Accelerating E-Motor Innovations

Our Technology Edge

Sustainable Materials >>

-

From neodymium in permanent magnets to copper in windings, the selective use of critical raw materials (CRMs) helps e-drive systems reduce supply risk and costs while preserving top-end performance for demanding applications.

Green Manufacturing >>

-

3D printing technology enables design freedom, cost-effective small-series production, and scalability without tooling investment — ideal for rapid iteration and low-risk scale-up. Furthermore, aluminum windings are lighter, more affordable, and outperform copper in high speed applications.

Durable Solutions >>

-

The power of a wire comes from the strength of its insulation and heat management. Our proprietary coating is applied after the winding is shaped, ensuring a defect-free dielectric layer. Together with advanced cooling solutions, this results in durable insulation, higher power density, and higher reliability under extreme stress.

Impactful Results

-

In high-frequency applications, Drive13 motors achieve market-leading power density enabled by optimized designs and the intrinsic advantage of aluminum’s lower AC losses compared to copper.

-

Our choice for aluminium offers the quickest and most affordable path to functional prototypes, due to our use of additive manufacturing and the absence of tooling costs. Drive13 will turn your innovative concept into an affordable reality.

-

Drive13 only applies its proprietary coating in the final production step, eliminating the introduction of mechanical stresses. In doing so, we can produce long-lasting windings, free from microcracks and partial discharges, a critical benefit for aerospace and other high-reliability sectors.

Why Working With US

Our know-how and expertise can support your complete design cycle. Drive13 engineering team acts as both technology partner and manufacturing expert.

Full engineering support

Drive13 is an experienced partner for advanced electromagnetic and thermal management solutions, for various topologies including radial and axial flux motor designs. Most of our solutions are available through parameterized motor models. This reduces the design cycle time and allow for fast execution.

Fast lane to solutions

During the past years, Drive13 R&D team developed a large set of innovative motor winding solutions, taking advantage of the unique in-house capabilities. While working with Drive13, You’ll get access to a wide range of groundbreaking validated designs and test results.

Validated innovation

Fast EXECUTION for FAST MARKET

In many fast-changing markets, We deliver solutions precisely suited to your application—wherever you are positioned in the value chain:

Tier 1 System integrators

We work alongside your engineering team to co-develop smart, manufacturable solutions tailored to your application, timeline, and performance targets.

Drive13 technology will reduce lead times, cut costs, and unlock new design freedom. You will surprise your end customers in terms of performance and development speed.

High end & mass markets

We have the in-house technology to make a winning solution in high end markets:

High-performance sectors like (aero)space, racing, and speedboat

Mainstream applications needing fast, innovative, cost-effective prototyping

Drive13 accompanies you from the early design stage to series production.